A group of ten Paraguayan technicians are gaining practical expertise in mould and die manufacturing as part of a specialised auto parts training programme in South Korea. The goal is enhancing Paraguay’s role within the international supply chain for automotive and electric mobility components.

The ten professionals, selected from nearly 40 candidates, are currently undertaking a four-month auto parts training programme in South Korea. This programme focuses on mould and die making, an essential element in global automotive industry operations. The initiative is being conducted at the Korea Die & Mould Industry Cooperative (KODMIC) in Siheung-si, Gyeonggi-do.

Auto parts training for manufacturing future

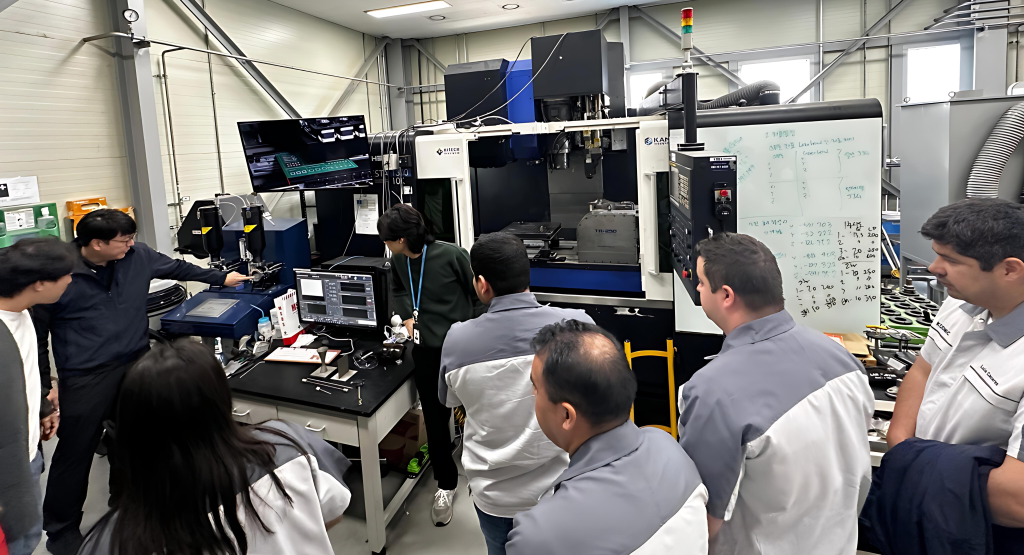

The group, composed of Luis Cáceres, Welington Báez, Jens Krauch, Ulises Szumega, Gisselle Uldera, Tiago Chamorro, Guido Martínez, Micaela Ramírez, Pedro González, and David Vente, is receiving 99 hours of monthly instruction, combining theoretical and practical training. The courses include mould theory, mould machining, Computer Numerical Control (CNC) machining, and mould design. These training sessions equip participants to actively apply their new knowledge when they return to Paraguay.

The programme forms part of the “Support Agreement for the TASK Paraguay Centre for Auto Parts and Pilot Project for Sustainable Electric Mobility”. This is a collaborative initiative between Paraguay and South Korea. It is supported by ITAIPU Binacional, the Paraguayan Ministry of Industry and Commerce, Korea’s Automotive Technology Institute (KATECH), and the Itaipu Technology Park (PTI-PY).

Learning from industry leaders

Beyond classroom instruction, participants have visited leading Korean institutions such as the Korea Institute of Industrial Technology (KITECH) and Silla Engineering. This is where they observed high-level industrial processes in real time.

Previous editions successfully trained 20 professionals. The inclusion of the group brings the total to 30, with a further 10 expected to be trained in 2026. This current phase at the KODMIC facilities in Siheung-si, Gyeonggi-do will continue until 20 August. The group has expressed great enthusiasm about applying newly acquired techniques to help build Paraguay’s industrial future.

Paraguay is taking strategic steps to strengthen its industrial capabilities, with young professionals leading the way. The auto parts training also fosters intercultural technical collaboration and long-term cooperation between institutions. This cooperation aims to positioning Paraguay as a future hub for automotive component production. This initiative aligns with the country’s broader push for sustainable innovation, including incentives for sustainable mobility, designed to promote electric and hybrid vehicle adoption nationwide.